具有獨特的使用壽命和無與倫比的總體擁有成本 (TCO)

我們廣泛的解決方案包括您所需的一切 - 從帶有可互換產品入子的模組化模具到定制的單一材質和多材質應用模具。我們依靠經過驗證且100%模腔內部平衡的冷流道技術,設計具有開放式冷流道系統和封閉式針閥澆口的射出成型模具。

透過我們,您將找到適合您生產要求的最佳化系統,無論是單穴還是256穴模具。我們了解需求的多樣性,並為各種生產環境提供量身訂製的解決方案。

我們的專業知識和對細節的關注使我們能夠生產出不僅生產率高而且使用壽命長的模具,同時最大限度地降低您的總體成本。依靠我們豐富的經驗和對最高品質的承諾,獲得您可以信賴的模具。

請立即聯絡我們,詳細了解我們如何協助您開發和製造符合您特定要求的優質高效模具。

1 cavity thermoplast mold + 1-cavity LSR mold

2 K - 2 component injection moulding

TP material: Polypropylene

TP gate technology: Valve gate

Elastomer material: UV-curing LSR

Elastomer gate technology: Valve gate

Demolding: Gripper EOAT on linear robot

1 cavity thermoplast mold + 1 cavity LSR mold

2 K - 2 component injection moulding

TP material: Polypropylene

TP gate technology: Valve gate

Elastomer material: UV-curing LSR

Elastomer gate technology: Valve gate

Demolding: Vacuum EOAT on linear robot

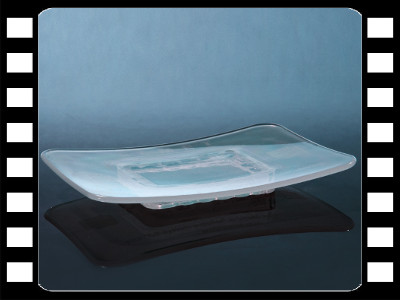

2 cavity mold with ejector side on turntable

Gate technology: Film

Elastomer material: LSR

Demolding: Vacuum EOAT on robot

Parts analysis with camera

4 cavity mold

Elastomer material: LSR

Gate technology: Open tip

Demolding: Gripper EOAT on linear robot

4 cavity slide mold

Elastomer material: LSR

Gate technology: Open tip

Demolding: Gripperhead on ELMET handling

4 cavity mold for overmolding thermoplastic part

Elastomer material: Selfbonding LSR

Gate technology: Open tip with sprue

Demolding: Gripper EOAT on linear robot

Preheating oven with trays

1+1 cavity thermoplast mold + 1-cavity LSR mold

2 K - 2 component injection moulding

TP material: Polyamid

TP gate technology: Valve gate

Elastomer material: LSR

Elastomer gate technology: Open tip

Demolding: Gripper EOAT on linear robot

In-mold assembly

8 cavity mold

Elastomer material: LSR

Gate technology: Valve gate

Demolding: Compressed air

16 cavity mold

Elastomer material: LSR

Gate technology: Valve gate

Demolding: Stripper EOAT on ELMET handling

64 cavity mold

Elastomer material: LSR

Gate technology: Open tip

Demolding: Ejector EOAT on ELMET handling

256 cavity mold

Elastomer material: LSR

Gate technology: Open tip

Demolding: Gripper EOAT on ELMET handling