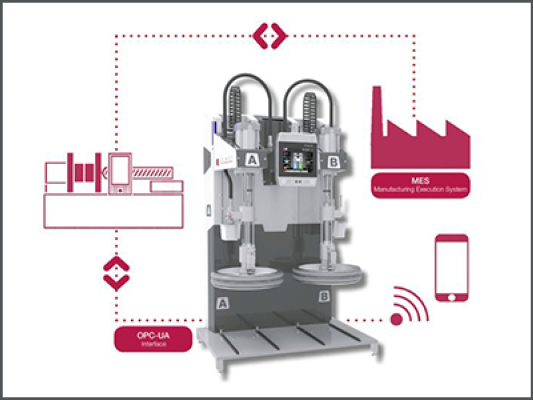

Oftering, Austria, May 2024 – In the run-up to the official market launch of the new TOP 700 LSR dosing system, Elmet was able to win over its long-standing customer Trelleborg in Switzerland as a development and test partner. Trelleborg received the new system two months before the planned market launch in order to subject it to comprehensive practical testing under real conditions in Stein am Rhein (Switzerland).

The close cooperation between Elmet and Trelleborg proved crucial in fine-tuning the system, which was finally presented to the public at NPE in Orlando, Florida, on May 6, 2024. Harald Wallner, CEO of Elmet, was very positive about the cooperation and emphasized the importance of Trelleborg's feedback for the continuous improvement of Elmet's developments.

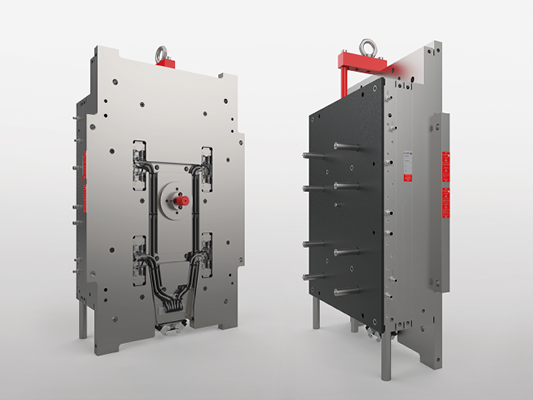

The TOP 700 marks a groundbreaking innovation in the areas of compactness, process stability, energy efficiency and cost-effectiveness. Specially designed for demanding applications in the medical technology, food and optics sectors, the system meets the strict requirements of the FDA and EMA.

Its compact design positions the TOP 700 as the smallest 20-liter system on the market, while meeting the industry's complex needs for efficiency and process stability. The emphasis on high precision when dosing silicones and additives is in line with the high standard that Elmet has already established with its flagship TOP 7000 Pro dosing system.

Elmet's ambition to drive the future of dispensing liquid silicone rubber and other materials is in line with its commitment to always set the highest standards in terms of safety, ease of use, quality, precision and efficiency.

f.l.t.r.: Oliver Hafner, Engineering Director, Trelleborg, Harald Wallner, CEO Elmet, Gerd Reichenbach, Senior Development Engineer, Trelleborg; © Elmet