Silicone molded parts are mostly produced using the LIM (Liquid Injection Molding) process. In this process, accurate temperature control plays a decisive role in achieving top product quality. Our standardized and ajustable cold runner systems – SMARTshot P and SMARTshot E – ensure precisely controlled material feeding right up to the cavity. This prevents any premature cross-linking of the material and enables precise, waste-free production through direct injection.

Our systems are tailored to specific customer requirements to match the perfect balance between standardization, efficiency, and flexibility.

Two technologies, one goal: maximum process control

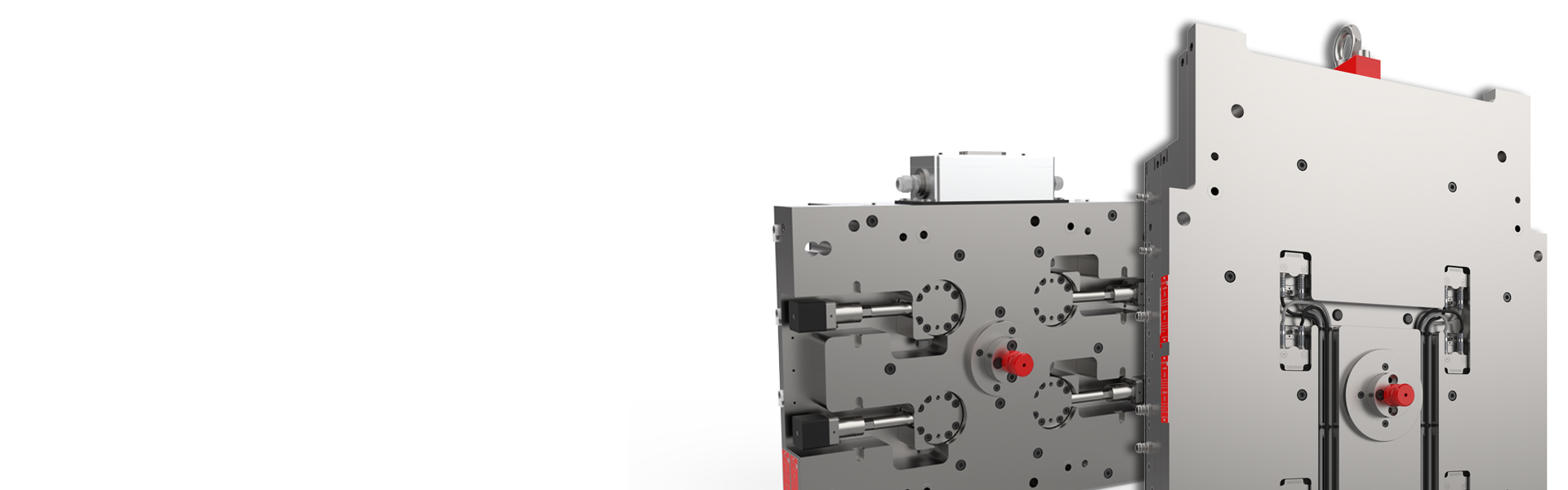

SMARTshot P, the universally employable classic among valve-gated cold runners: robust, compact, and versatile. It is ideally suited for all standard mold concepts and injection molding machines

Proven and easy to handle

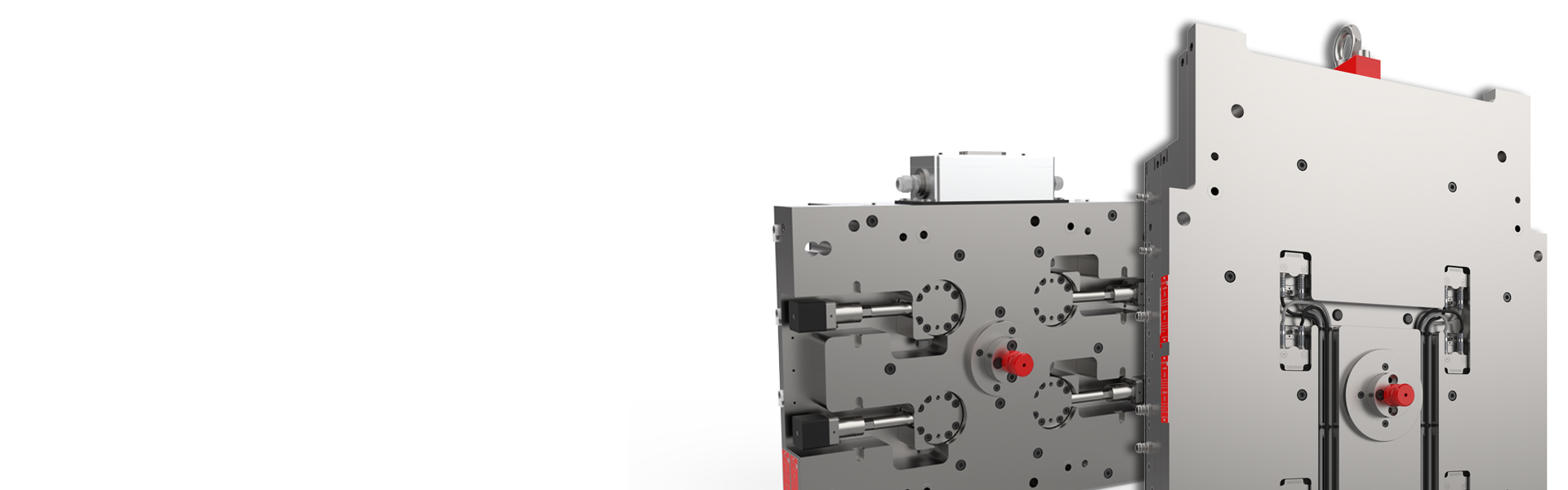

The fully electric SMARTshot E takes cold runner technology to the next level. Featuring a precision servo drive, narrow spacing between nozzles, and full process integration, it constitutes the ideal solution for the most challenging demands.

Smart Control for highest operator comfort

Designed to be compact: cold runner innovations

Efficient processes: clean, fast, efficient