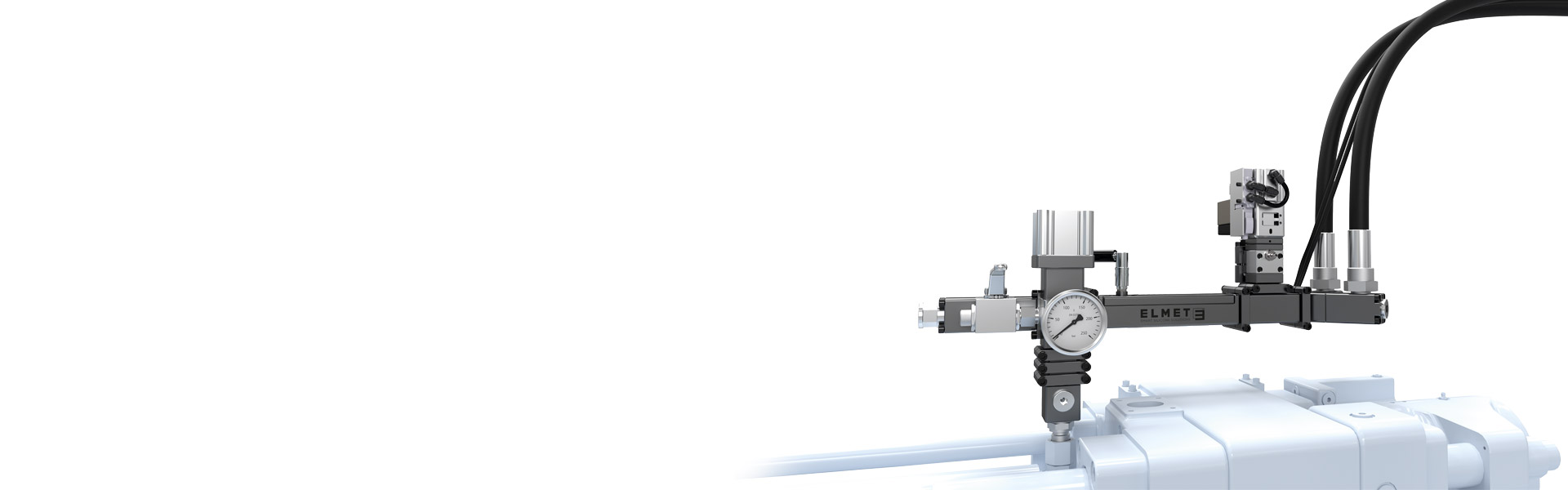

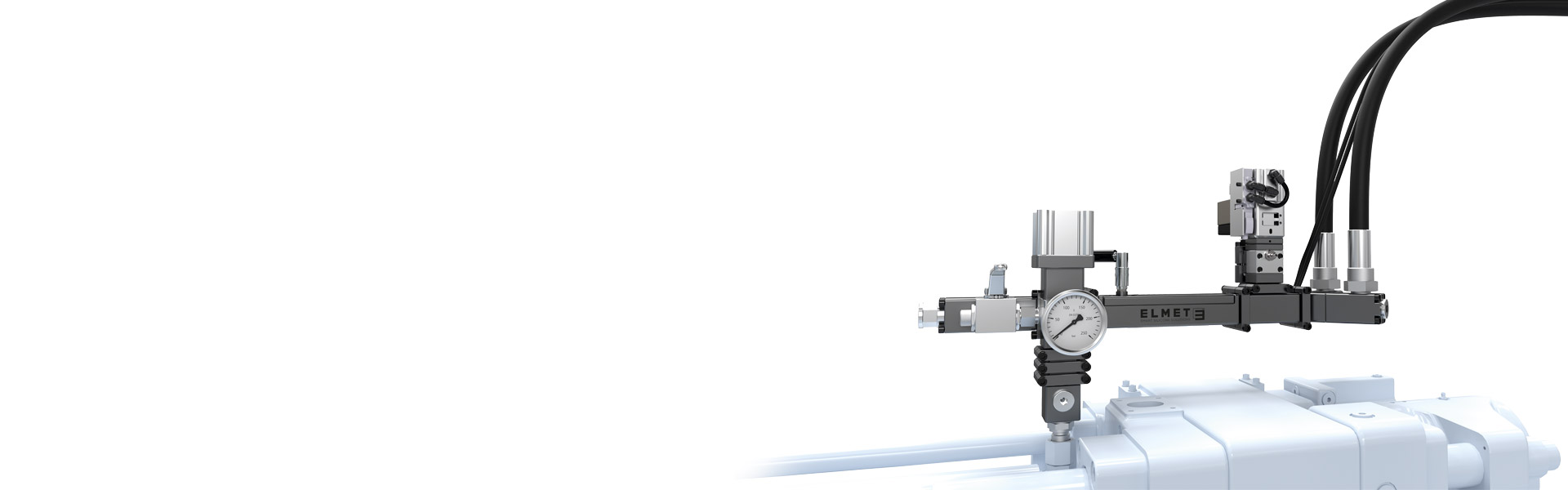

In the processing unit, A and B components are mixed with the pigment and additive streams. Thanks to sophisticated technology, the high pressure of the compressed liquid silicone rubber is optimized and maintained at a constant, adjustable level by a pressure limiter. ELMET has perfected this technology so that it can be even used in the extrusion process without problems. Here too, ELMET is setting a new benchmark.