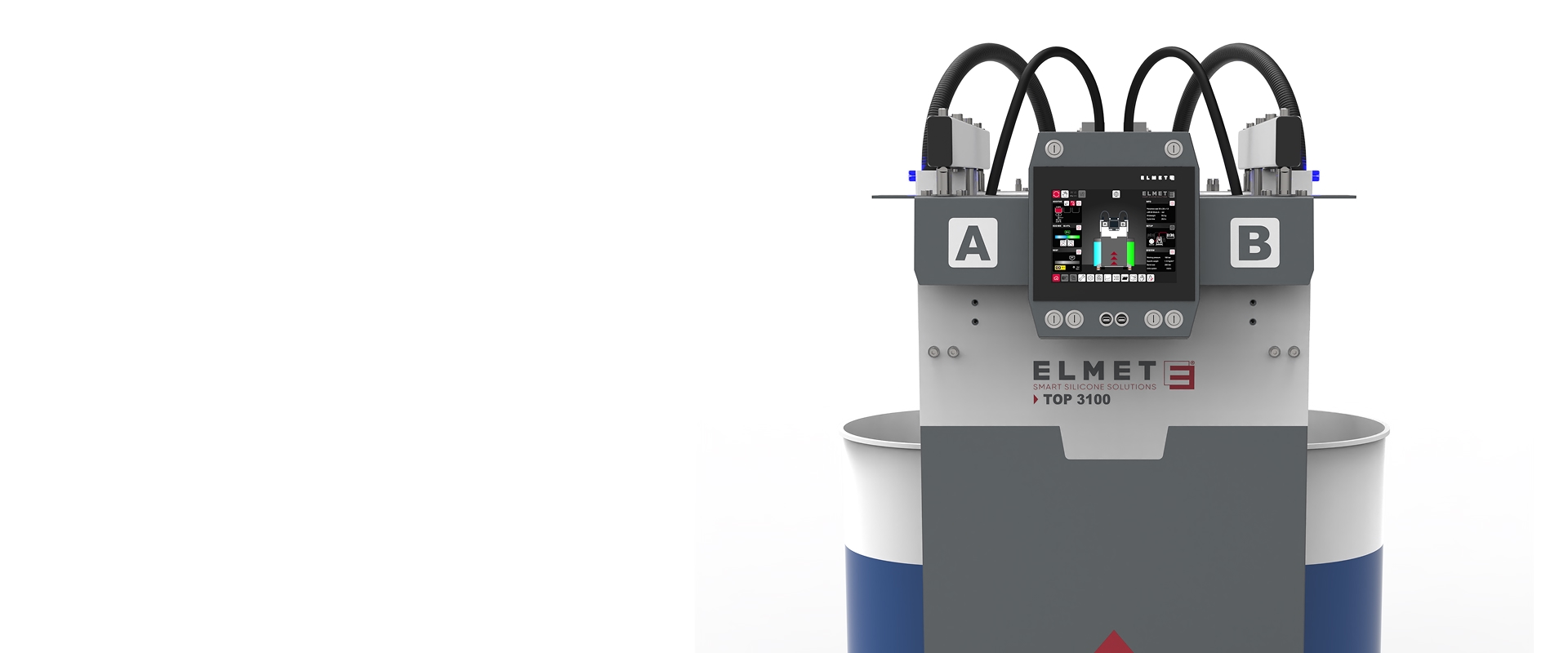

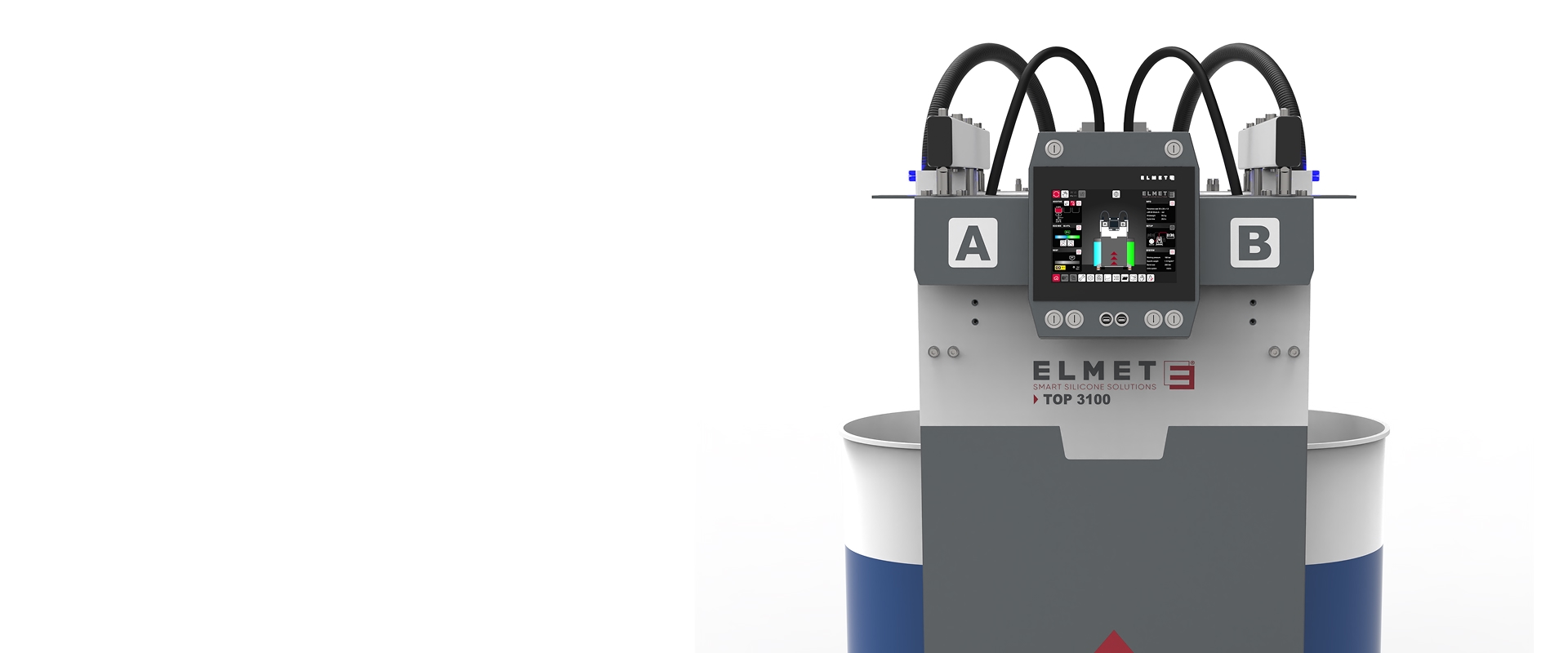

With its TOP 3100, ELMET offers a dosing system that focuses on the essentials without making any compromises in terms of quality, process reliability, or longevity.

Designed for cost-conscious users and those new to LSR processing, the system combines outstanding precision with robust technology, delivering excellent value for money.

The TOP 3100 impresses with its clear operating logic, compact design, and reliable functionality. Silicone and additives are processed on the basis of a precise mixing ratio, efficiently and safely. The system competently covers around 90% of all common LSR applications.

With this model, ELMET expands its product portfolio with a cost-effective solution that sets a new standard in the entry-level segment. Perfect for all users looking for efficiency and quality in a compact package.

30 years of ELMET – 30-month warranty

ELMET dosing systems purchased in the anniversary year 2026 are automatically covered by a 30-month warranty.

Valid for direct purchases from ELMET. Worldwide, except Asia. The general warranty conditions for ELMET dosing systems apply.

High performance

Stable & precise

Cost effectiveness

Energy efficiency

Versatile in use

Safety

User friendly

* measured with silicone oil at ẏ=10 1/s η = 2.7 Pas (A+B components) | ** ẏ=10/s | *** ẏ=0.2/s

Safety is ELMET's top priority.

With our dosing systems, we are not only setting new standards in terms of energy efficiency, performance, and process stability, but also in the area of machine safety. Our systems meet the highest standards and have been successfully tested and inspected by TÜV SÜD.

This means we can offer you the demonstrably safest dosing system in the market.

Fix-Mix

freely selectable mixing ratio

Barcode drum detection

Drum lifting device

Wheels

Customized paint work

Process documentation

OPC UA

Remote monitoring via VNC

Premium Connectivity

Simplex

1 dosing system on 2 injection molding machines

Tandem

2 dosing systems in alternating operation

SMARTsupport Hub

Maximum system availability through smart remote support

Try out our dosing systems free of charge and without obligations

Save energy & reduce CO2 emissions

Forget the myth that pneumatic dosing systems always consume more energy than electric ones. ELMET technology proves the opposite – and sets new standards:

Up to 50% less energy consumption compared to purely electrically operated pumps – that means:

Lower CO2 emissions

Lower operating costs

Greater sustainability