Process stability is the decisive quality feature of dispensing systems. The TOP 7000 Pro dosing system not only guarantees the highest part quality, but also reliable continuity. Thanks to the precise mixing ratio of silicones and additives and the outstanding efficiency of the system, the TOP 7000 Pro sets a new benchmark in the market.

POWERFUL

► Maximum process stability thanks to integrated high-precision volume counting

VERSATILE IN USE

► Intuitive and simple operation

USER-FRIENDLY

► Air detection

Safety is our top priority. Not only do we set new standards in terms of energy efficiency, performance and process stability, we can also proudly claim to have the safest dosing system on the market. This high safety standard is confirmed by the successful inspection by TÜV SÜD.

Our TOP 7000 Pro meets the following standards:

► DIN EN ISO 13849-1

► DIN EN ISO 13851

► ÖNORM EN ISO 12100

► ÖNORM EN ISO 13857

► ÖNORM EN ISO 13849-2

In addition, our systems are CE, UL (Underwriters Laboratories) and RoHS certified.

We guarantee that our dosing systems meet the highest safety, quality and environmental standards and therefore comply with all legal requirements and market demands - that is our claim for our dosing systems.

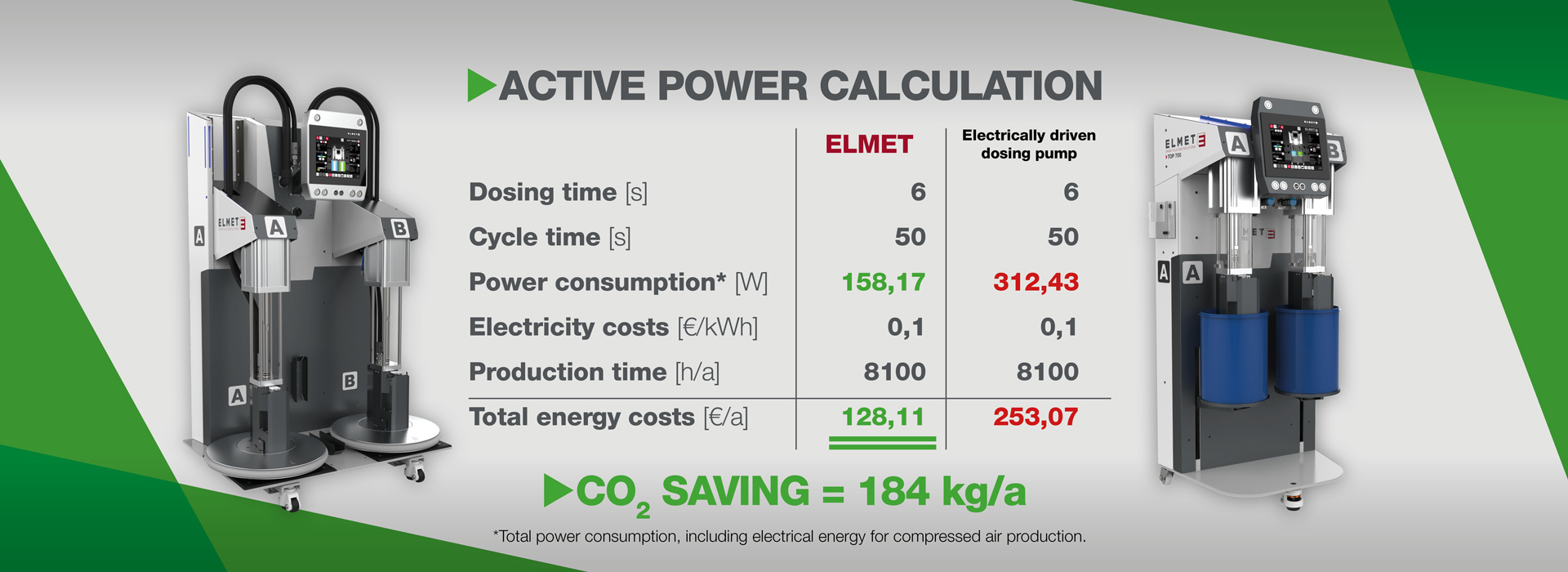

Put an end to the myth that pneumatically driven dosing systems consume more energy than purely electric systems. Elmet dosing systems set new standards: our technology requires up to 50 %* less energy than purely electrically driven pumps and reduces your CO2 emissions, which protects the environment and saves costs.

Compressed air is one of the most expensive energy sources! That's right!

But when used correctly, compressed air can even save energy, as comparative measurements on various dosing systems show. Since compressed air as a pneumatic spring is a perfect energy store, ELMET dosing systems consume virtually no energy while they are being serviced. With an idle power consumption of just 50 Wh and an average energy consumption of 150 to a maximum of 400 Wh, compressed air even beats all-electric systems.

WHAT DOES THAT MEAN FOR YOU?

► Reduced energy consumption

Elmet dosing systems consume up to 50 % less energy compared to purely electrically operated pumps. This leads to considerable energy savings.

► Cost savings

Reduced energy consumption reduces operating costs, which leads to a reduction in overall production costs.

► Environmental friendliness

Less energy consumption also means a lower CO₂ impact and therefore a smaller ecological footprint. This supports environmentally conscious production goals.

► Competitive advantage

Companies that use energy-efficient technologies can position themselves better on the market and highlight their sustainability efforts.

► Greater efficiency

The optimum energy efficiency of Elmet dosing systems can contribute to a better overall performance of the production plant.

Choose a sustainable future - choose Elmet!

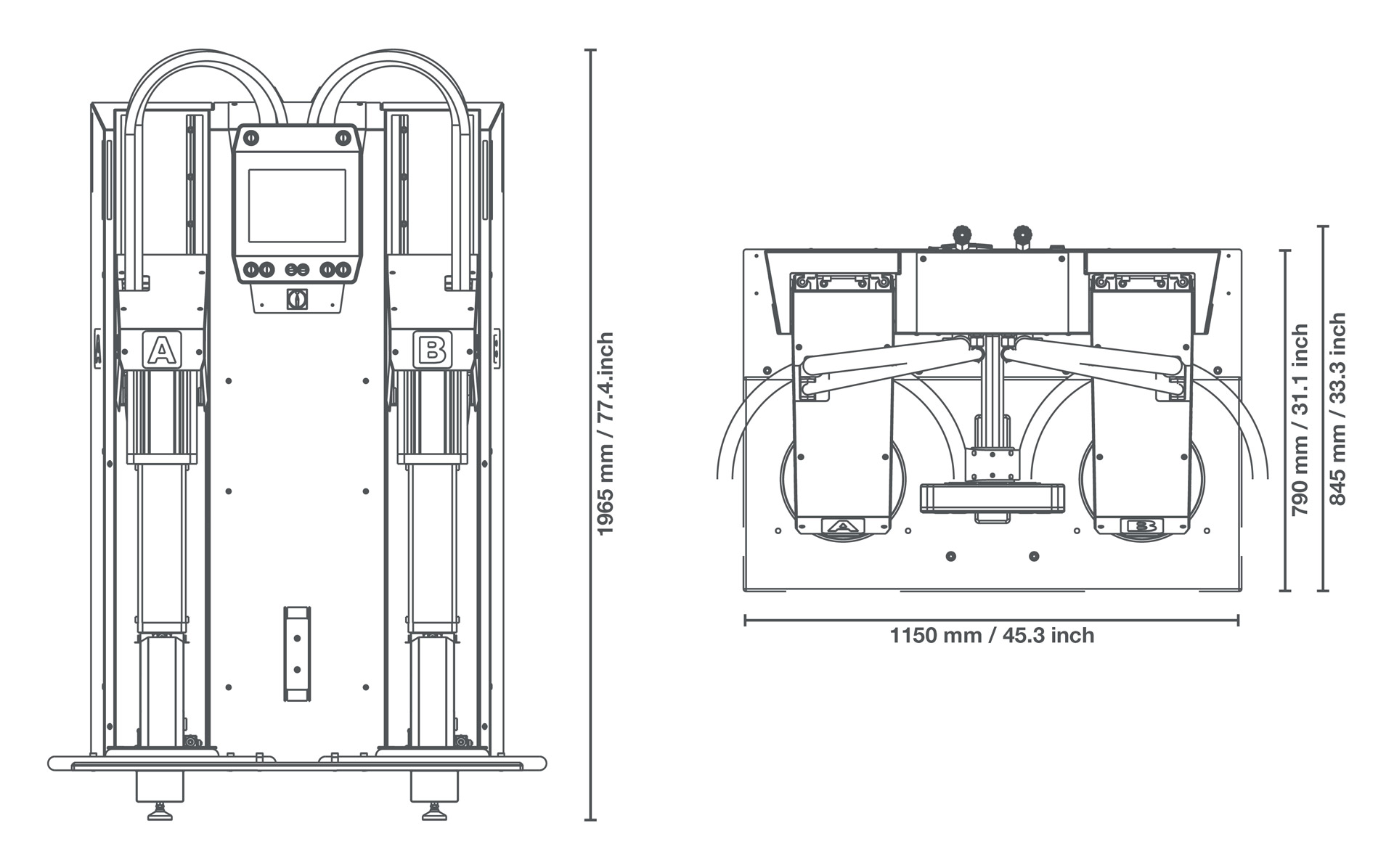

► Dimensions L/W/H: 1150 x 790 x 1965 (mm) | 45.3 x 31.1 x 77.4 (inch)

► Drum sizes: 200 / 20 liters | 55 / 5 gallons

► Drum change: 3 sides (180°) in 2 minutes automatically guided

► Usable materials [Pas]**

Pump unit S: 0.001 to 2000

Pump unit M: 0.001 to 3000

► Discharge rate per component @ 2.7 Pas

Pump unit S: > 2500 cm³ / min

Pump unit M: > 2350 cm³ / min

► Maximum delivery pressure

Pump unit S: 210 bar / 3046 psi

Pump unit M: 230 bar / 3336 psi

► Power supply: 100 - 264 VAC, 4 A

► Air supply: 6 bar – 1000 NL / min (1/2“)

► Additive lines: max. 6

► Mixing elements: 1 Standard to 10 Optional

► Volume counter: Yes

► Certifications: CE, UL, FDA, EMA

► Simultaneous drum emptying (Eco-Mix): Standard

► Process documentation USB: Standard

► Freely selectable mixing ratio (Fix-Mix)

► Shore-Mix

► LSR Select

► Barcode drum recognition

► Drum lifter

► Wheels

► Customized paint work

► Process documentation OPC UA

► Euromap 82.3

► Remote maintenance via VNC

► Premium Connectivity

► Simplex (two-machine operation)

► Tandem (no production downtime during drum change)

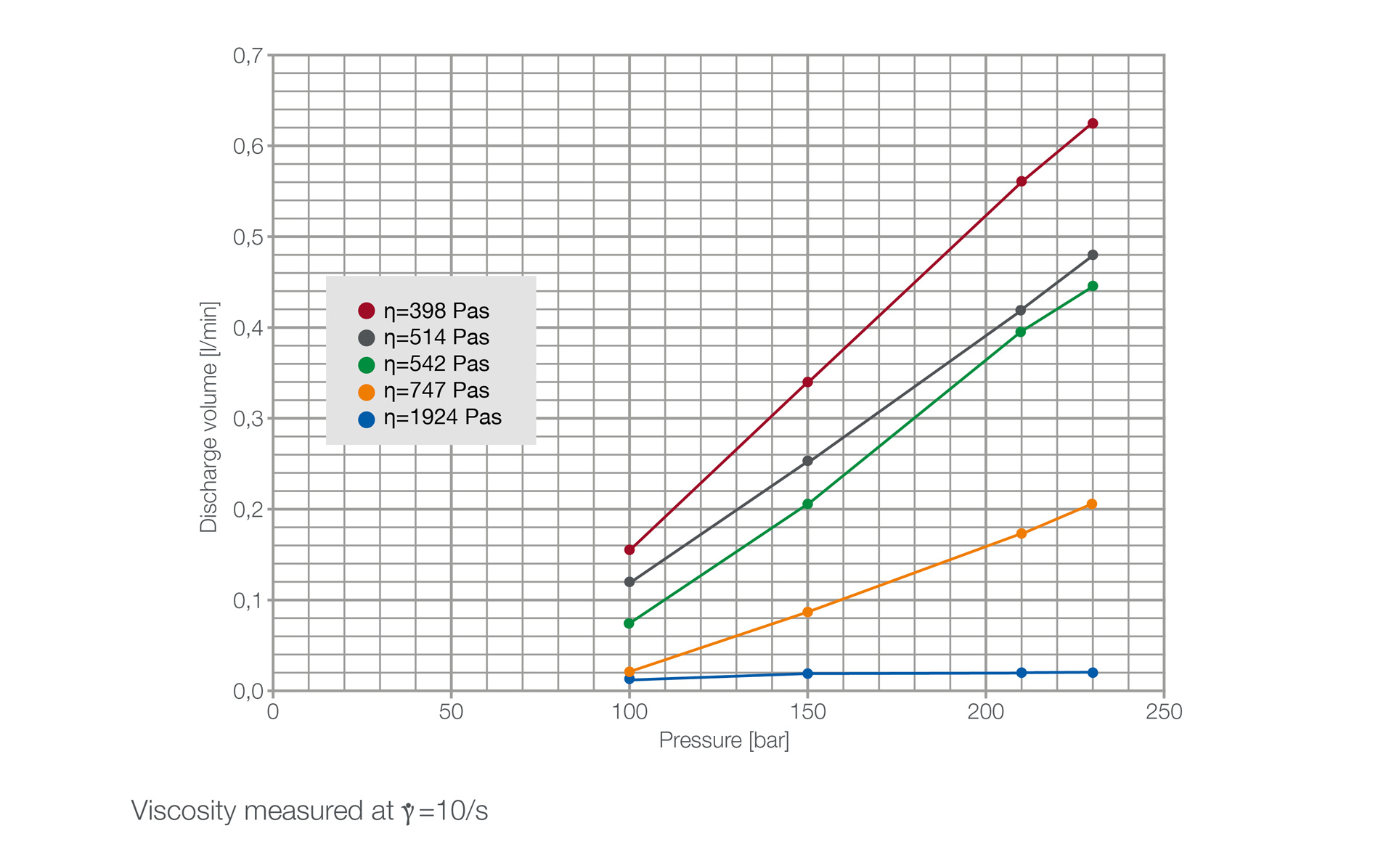

The TOP 7000 Pro dosing system is now also available in a version with the new M pump unit.

The new M pump unit impresses with its innovative design and an upstream pre-feed plate. This combination makes it possible to process a very wide range of viscosities, especially with very stable materials such as carbon black-filled types or self-adhesive materials that tend to increase in viscosity, and with only a slightly lower discharge rate compared to the S pump unit.

Thanks to these properties, the M pump unit can process all LSR materials available on the market. Existing TOP 7000 Pro dosing systems can be easily converted from S to M or vice versa, depending on requirements.

In the processing unit, the A and B components are mixed with the pigment or additive streams. The high pressure of the compressed liquid silicone is fl ow-optimized thanks to sophisticated technology and kept at a constant, adjustable discharge level by a pressure limiter. ELMET has perfected this technology so that it can even be used in the extrusion process without any issues. Here too, ELMET is setting a new benchmark.

► Modular design

► Integrated cooling

► Laminar fl ow optimized (no dead corners)

► Simple clamp-connection design

► 45° & 90° connections for easy adaptation to any system

► Up to 6 additive lines can be used per unit

► Simple cleaning

► Minimum material cross-sections with maximum possible throughput

► Economically sophisticated – material minimization in the system

Pigments and additives are valuable parameters in the LIM process. ELMET therefore relies on high-precision pigment and additive lines developed in-house. The dosing is adjusted to the actual measured volume flow of the components. Optional control systems can permanently readjust and thus increase the precision even further.

► Additive container 1 l / 4 l / 20 l

► Volume counter (resolution < 0.1µl/l)

► Simultaneous drum emptying A+B (Eco-Mix) or freely selectable mixing ratio (Fix-Mix)

► Barcode drum detection

► Remote control via VNC

► OPC-UA | Euromap 82.3

► Fix-Mix mixing ratio

► Premium Connectivity package incl. app for iOS & Android

► Elkem LSR Select